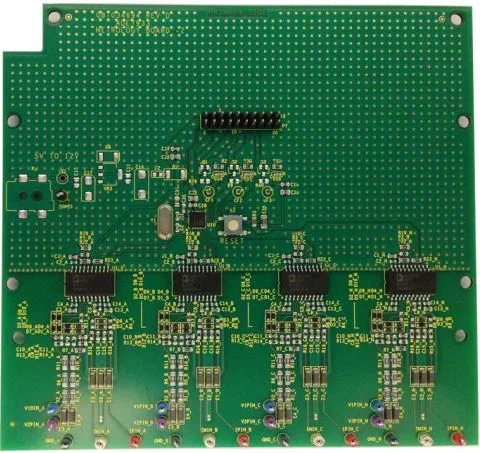

Jeking provide all-in-one OEM Printed Circuit Boards. We design and manufacture PCB and populate them with components to achieve a custom designed board to meet customer requirements. This ensures all client products meet the quality and performance targets set by each industry.

Customization Capabilities of OEM PCBA Services

The specific requirements of every project can be catered to with the following customization options available in the OEM PCBA services:

Choice of Materials

Clients are able to select from a range of PCB materials such as FR-4, Rogers, Teflon and Aluminum clad boards based on the application's electrical, thermal, and mechanical needs.

Component Procurement

Clients are not limited to sourcing components from a single supplier. OEM PCBA service providers have access to a variety of suppliers which guarantees quality components will be procured for the assembly process.

Design Flexibility

We can design bespoke PCBs within specific dimensions and accommodate intricate designs and tight spacing restrictions.

Assembly Techniques

Various assembly techniques need to be used like surface mount technology (SMT) and through-hole technology (THT), depending on the project’s complexity and robustness.

Testing and Validation

Rigorous testing and validation throughout the construction and assembling phases provides assurance for the performance metrics set for the PCBs during assembly.

The Importance of Customization in OEM PCBA

There are several reasons as to why the OEM PCBA services are vital from a customization perspective.

Meeting Specific Industry Standards

Every sector has its own standards and regulations that have to be tailored to, all of which are not universal. Without such alterations, the final product would be ineffective for the expected purpose.

Enhancing Product Performance

To ensure performance is at its best, there are many parameters to be factored such as signal integrity, power consumption, and thermal factors. It is also essential that the PCB is tailored towards the goal to achieve set performance standards.

Accommodating Unique Design Requirements

Variation in design needs can also be fulfilled by variety of design elements such as special connectors or sensors that are not offered in standard PCB designs.

Customization for OEM PCBA services is crucial for developing bespoke electronic designs that conveniently satisfy different application needs. The products which Jeking provides stand for the flexibility and versatility of these services and are designed for and can be readily integrated into the client’s systems. With advancement in technology, demand for customization shall become an integral part of OEM PCBA, and that would mean improvement and new ideas in electronic manufacturing.